The challenge:

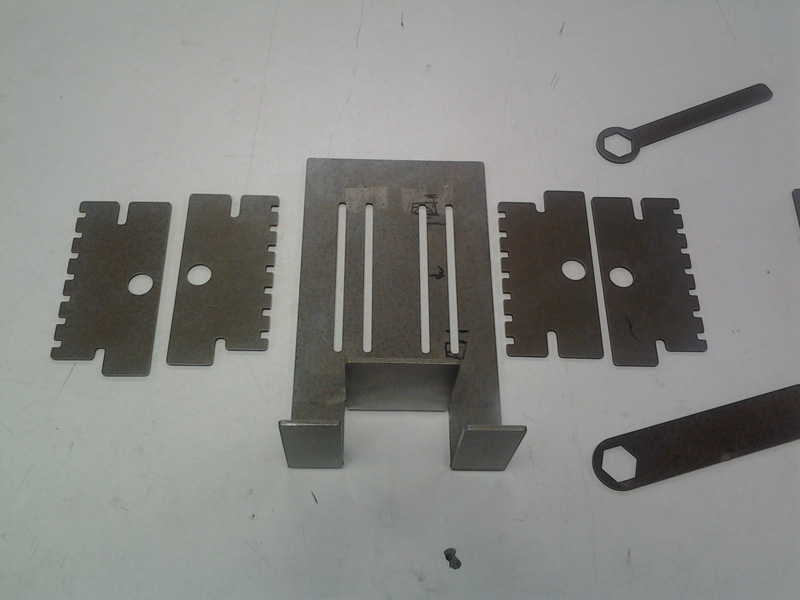

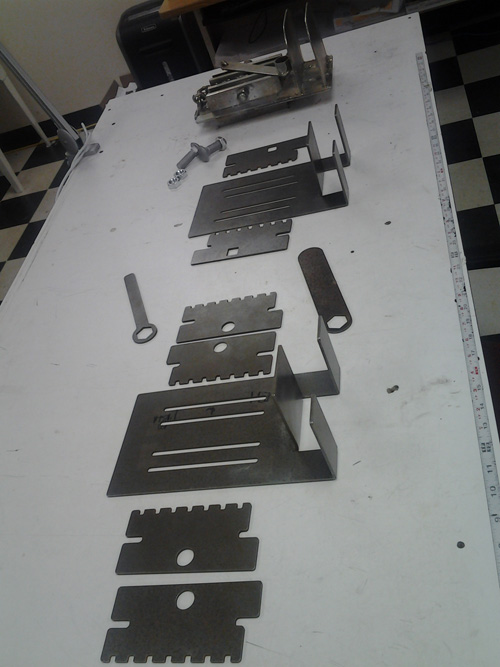

Our client had a very crude prototype fabricated without any computer aided design.

It was an extremely labor intensive fabrication consisting of many heavy gauge components welded together.

The challenge for us was to redesign the unit for cost effective volume manufacturing.

The solution:

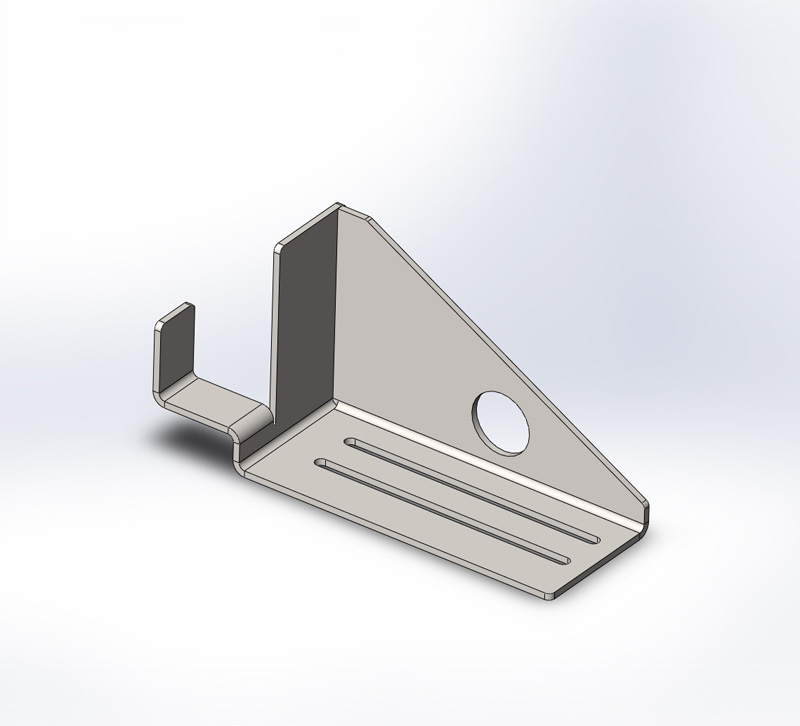

Our engineering team dissected the function of the product and strength requirements.

After this preliminary analysis was complete, we reviewed manufacturing methods and volume costs.

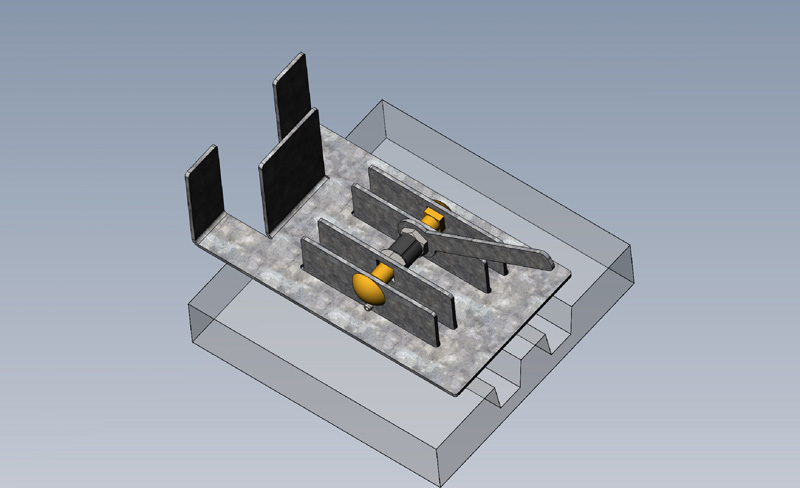

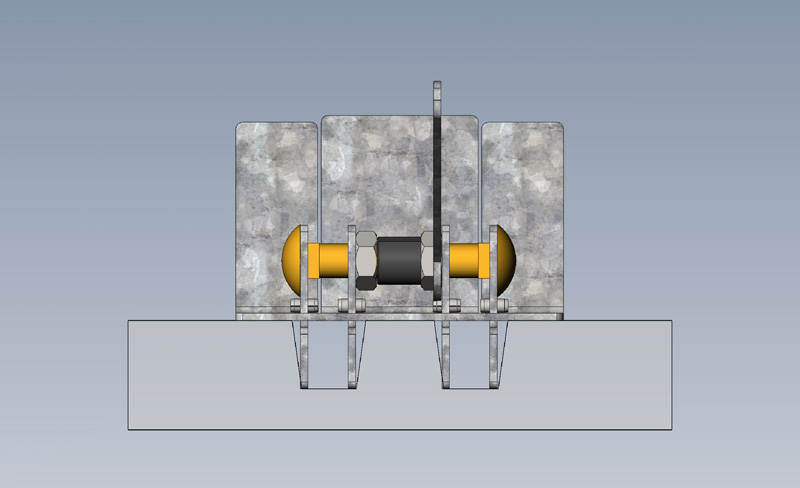

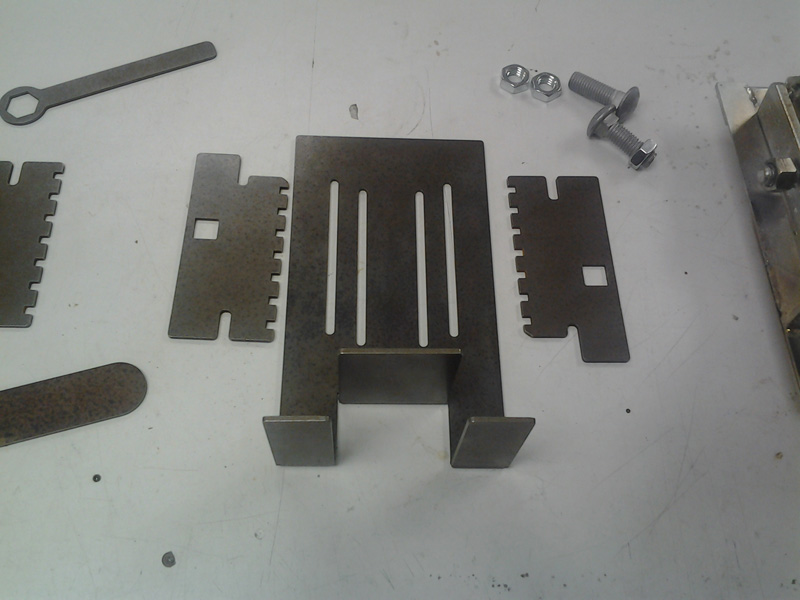

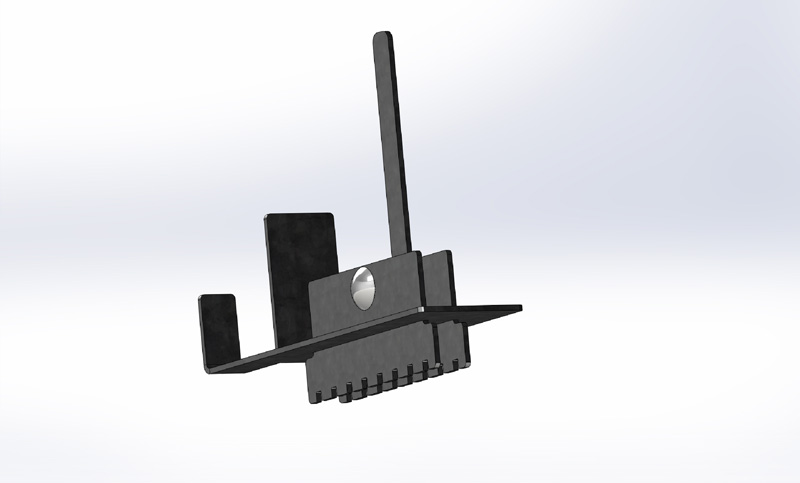

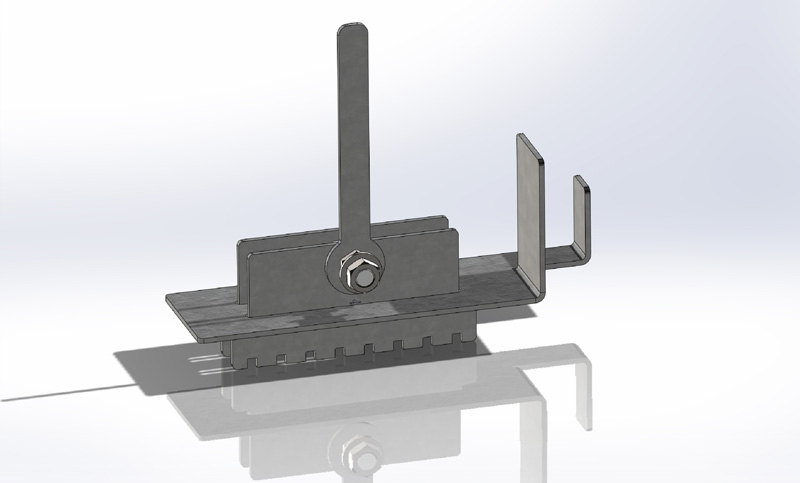

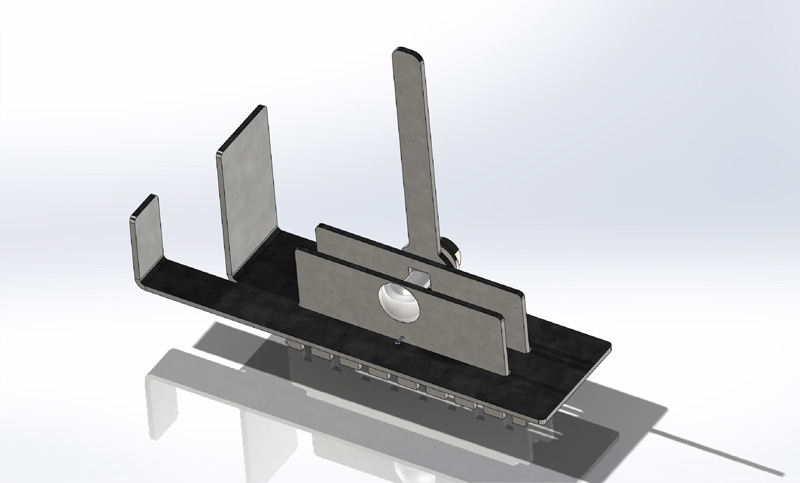

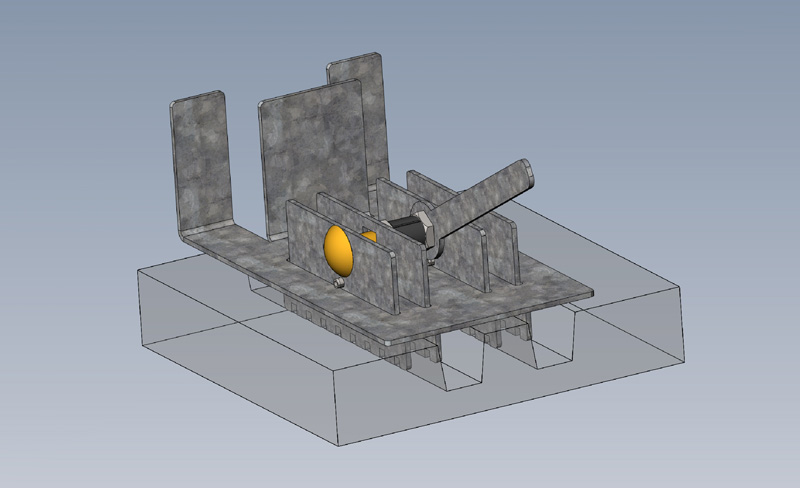

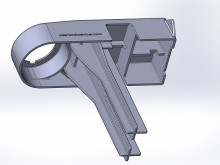

After evaluating these methods, sheet metal design met all requirements including cost.

We immediately performed Finite Element Analysis to reveal weak areas and enhance the design for strength and mechanical properties.

We enhanced the design based on the FEA findings.

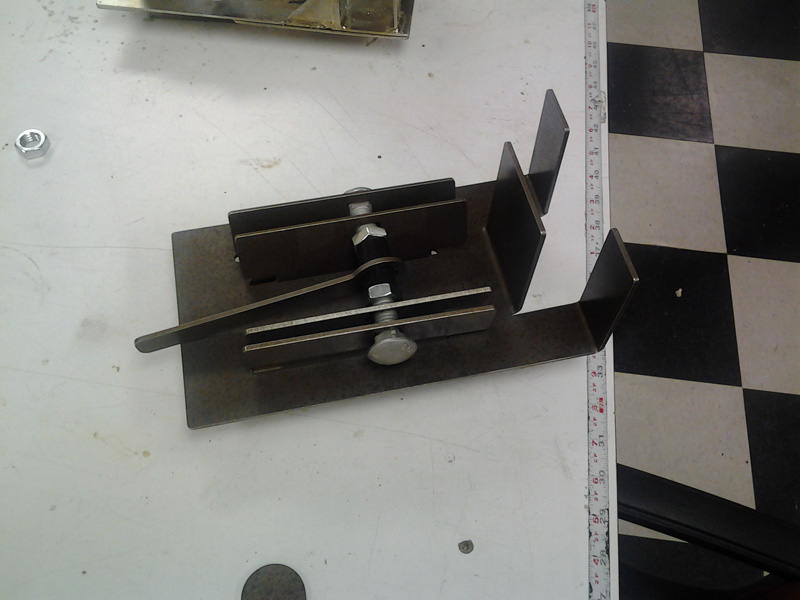

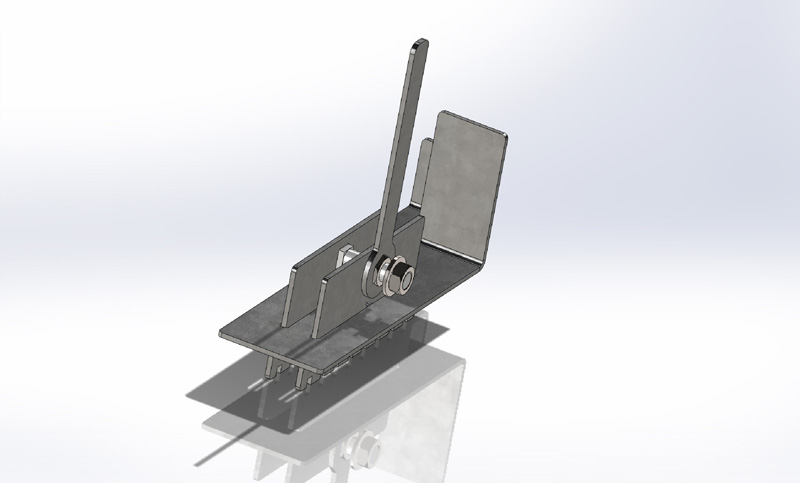

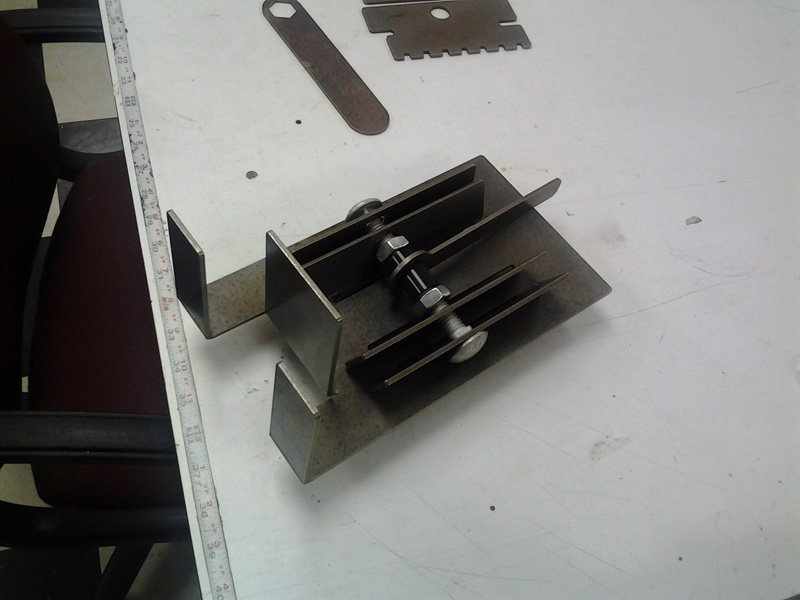

We then designed several configurations of the bracket assembly and fabricated prototypes for testing.

Conclusion:

After real life testing the different design configurations, one design stood out as superior in strength and cost to manufacture.

This design was approved and frozen by the client and is currently being deployed and used in their shipping containers today.